Shaabadda farsamada guga ee HJ92N ee warshadaha badda,

,

Astaamaha

- Looxyada aan la tallaabin

- Shaabad keliya

- Dheelitiran

- Ka madax bannaan jihada wareegga

- Guga wareegaya ee la duubay

Faa'iidooyinka

- Gaar ahaan loogu talagalay adkeysiga oo ay ku jiraan warbaahinta aadka u dhalaalaysa

- Biyo-mareennada ayaa laga ilaaliyaa badeecada

- Naqshad adag oo lagu kalsoonaan karo

- Wax dhaawac ah oo usha ah kama soo gaaro O-Ring oo si firfircoon loo raray

- Codsiga guud

- Kala duwanaansho loogu talagalay hawlgalka hoostiisa faakuumka ayaa la heli karaa

- Noocyo loogu talagalay qalliinka nadiifka ah ayaa la heli karaa

Kala duwanaanshaha Hawlgalka

Dhexroorka usha:

d1 = 18 … 100 mm (0.625″ … 4″)

Cadaadis:

p1*) = 0.8 calool xanuun…. 25 bar (12 calool xanuun… 363 PSI)

Heerkulka:

t = -50 °C … +220 °C (-58 °F … +430 °F)

Xawaaraha simbiriirixan: vg = 20 m/s (66 ft/s)

Dhaqdhaqaaqa Axial: ±0.5 mm

* Quful kursi oo aan joogto ahayn looma baahna gudaha xadka cadaadiska hoose ee la oggol yahay. Si loogu shaqeeyo muddo dheer iyadoo la isticmaalayo faakiyuum, waxaa lagama maarmaan ah in la diyaariyo daminta dhinaca jawiga.

Qalabka Isku-dhafka ah

Wajiga Rotary

Silikoon carbide (RBSIC)

Resin kaarboon graphite ah oo la dahaadhay

Kaarboon la dahaadhay oo Antimony ah

Kursiga Joogtada ah

Silikoon carbide (RBSIC)

Kaarboohaydrayt Tungsten ah

Shaabad Kaaliye ah

Kaarboon-Fluorocarbon-Taag (Viton)

Ethylene-Propylene-Diene (EPDM)

Gu'ga

Bir aan Daxal lahayn (SUS304)

Bir aan miridh lahayn (SUS316)

Qaybaha Birta ah

Bir aan Daxal lahayn (SUS304)

Bir aan miridh lahayn (SUS316)

Codsiyada lagu taliyay

- Warshadaha dawooyinka

- Tiknoolajiyada warshadda korontada

- Warshadaha saxarka iyo warqadda

- Tiknoolajiyada biyaha iyo qashinka

- Warshadaha Macdanta

- Warshadaha cuntada iyo cabitaanka

- Warshadaha sonkorta

- Wasakh, xoqid iyo adkeysi leh oo ay ku jiraan warbaahinno

- Casiirka qaro weyn (70 … 75% sonkorta ku jirta)

- Dhoobada ceeriin, wasakhda wasakhda ah

- Bamka dhoobada ceeriin ah

- Bamka casiirka qaro weyn

- Gudbinta iyo dhalada waxyaabaha caanaha laga sameeyo

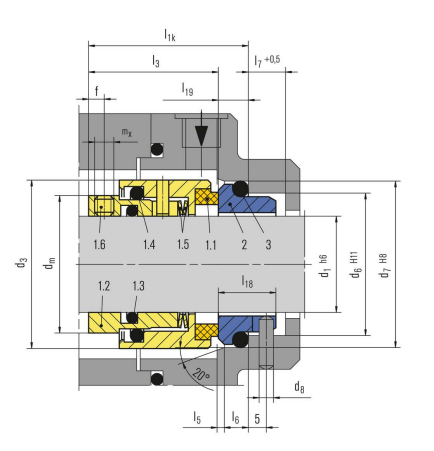

Qaybta Shayga lambarka DIN 24250

Sharaxaad

1.1 472/473 Wajiga shaabadda

1.2 485 Qoorta darawalka

1.3 412.2 O-Ring

1.4 412.1 O-Ring

1.5 477 Gu'

1.6 904 Boolal dejis ah

2 475 Kursi (G16)

3 412.3 O-Ring

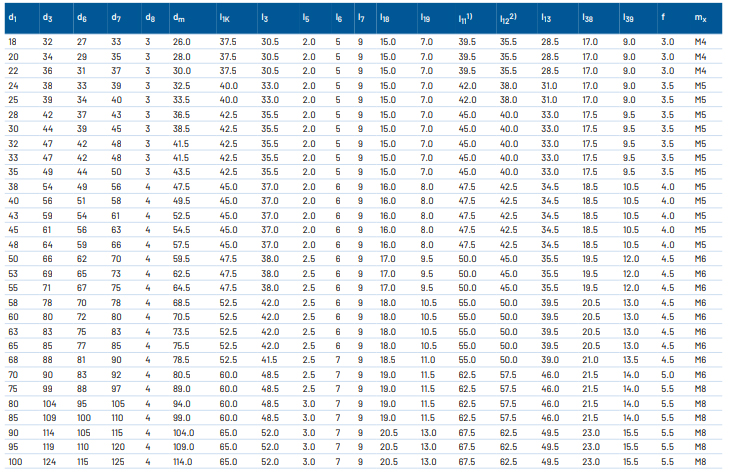

Xaashida xogta ee cabbirka WHJ92N (mm)

Shaabadda bamka farsamada HJ92N ee warshadaha badda

Shaabadda bamka farsamada HJ92N ee warshadaha badda